I must have sat through 3 to four presentations of IoT in

the last 2 weeks from different vendors, different industries. Combine this active

strategic discussions within our development teams, you see many angles and

thought approaches.

ARC’s definition:

“The industrial internet

of things is a collection of technologies that can come together in a

targeted solution to improve business performance

and machine availability”.

The key is the transition to information driven system

has begun and it is about alignment of devices, process and people, to be

effective in real-time agile production. Extending across the plant, and the

whole value supply chain, providing transparency in end to end operations.

All are valid, but the question was asked on a site visit

last week " what does it mean to us?". So I stood up and went to

white board and drew three circles and intersected them, to represent the

opportunity.

As you can see below in the diagram below:

The three circles were

1/ The Capital Assets,

these a non-living devices, such as instruments, machines, motors, conveyors,

tanks, PLCs, DCS, RTUs, switch gear, etc.

2/ The Human Assets:

all the workers and roles no matter of location, if they employees,

contractors, consultants, but are required for the efficient, timely operation

of the production facility.

3/ The Operational,

Product Processes, procedures that applied across multiple capital assets,

across workers, and between chapati all assets and workers to gain consistent

operations, production. Increased production consistency, increased utilization

of all resources both capital and human assets, making the most effective use

of resources such as materials and energy.

To many people refer to IoT are just looking at assets

and smart devices, and moving to asset management, this is only a initial step,

when you improve operational productivity out of the plant is when the paradigm

of value is achieved. To me it is not just about smart devices, it is about

combining this with proven production procedures, processes across the

different assets in plant, both human and capital in order to gain must effective,

efficient production.

Taking the customer a little by surprise, as they just

been hearing about smart devices, but when brought relative to their plant

reality sank in. Why is different to the traditional approach, is that when you

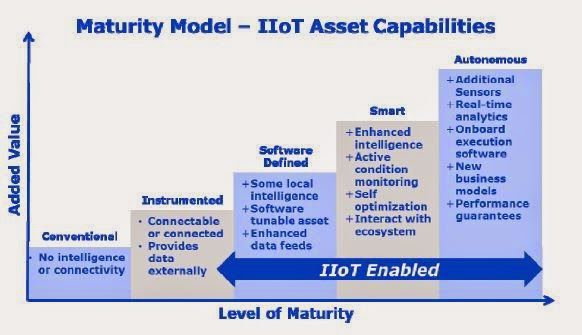

think as in diagram below (from ARC) maturity of devices in the IoT as they become smarter

to autonomous.

The devices, assets such as packaging machines, motors,

pumps, agitators become fully aware of what is running in them, What they are

meant to produce and how Their ability to achieve the desired result Their

health and readiness to perform to expected capabilities.

The machines move to been just apart of the team,

enabling awareness to operational workers as early as possible of abnormal

conditions that will effect production output, so " actionable

decisions" can be taken. So when I walked around their plant I found the

human assets all the different roles, and there were many, today they running

between fixed work stations, looking uncomfortable in executing tasks, and

doing paper inputs all over the place, totally in adhoc actions.

In the potential new world the human assets, are

empowered with devices, from small, to tablets, to PCS, but they aware,

connected, and the ability understand the situation. Combine this with the move

to embed experience in the systems, so actionable steps can be taken in timely

manner no matter where the worker is.

So the worker is :

- Now aware instantly of an up coming situation

- They can understand the context immediately

- They can make a decision

- They can take an action

All happening in real-time, no delays, and coordinated

through exception based machines, processes, and embedded experience, so now

assets, production and human workers are working as one.

Walking around this plant last week, the opportunity to take

small steps in a coordinated operations and empower the workers to be

effective, will yield significant returns. The internet of things in the industrial context is taking the operational / production co-ordination we have today to another level, extending the scope and understanding of workers, buy making capital assets and human assets apart of aligned team through embedded operational practices/ procedures.

No comments:

Post a Comment