“What does Operational Collaboration Mean for my Modern Supervisory System?”

Last week I travelled to Western Australia, a state where there is a significant mining boom, and a challenge of how to operate it’s plants with a 3 way changing market:

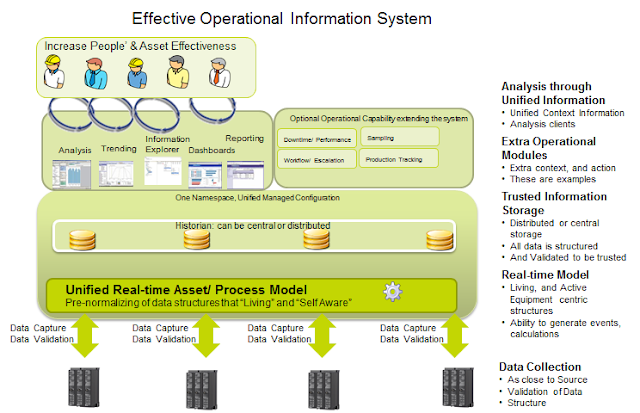

· The need to be agile to maximize production, which drives a push towards streamlining “Value Generating Assets”.

· The shortage of skill sets and experience

· The changing demographic of the workforce to a younger more “digitally native” aware personal

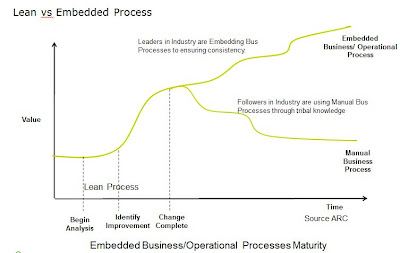

As I spoke with people in the industry from engineering to operations, the topics I have been discussing in this blog over the last couple of months were confirmed. It does require a different thinking on how to put a system together, and not just different technologies but also an awareness in the design of the system of the constraints these new dynamics bring. This is calling for a rethink of operational practices and collaboration in real-time, to enable the “Flexible Operational Team Work” required, this goes beyond “Operational Centers” it is a new level teamwork, which will require a new thought pattern when designing the operational systems.