I seem to have been involved in Smart Fields, Smart

Facilities, etc for years, and a lot of the discussion and thought leadership

was around information, and more intelligent devices. But many have had limited

success, until now, why is because many “smart” strategies did not cover all

the bases.

During last week a colleague and I had a number of workshop

sessions around forward strategy, reviewing specifically what is different this

time round with smart, looking at the “Operational Transformation” event we

seeing unfold, what is different and core this time! It was very clear, but so was the significant discontinuity in the market.

When we talk Smart concepts too often, the discussions goes

quickly to the “smart/ intelligent” devices, and data and information, with the

hype around the “Internet of Things” this continues. But when you really get down

to what people are trying to achieve is decisions faster, and flexibility /

agility through awareness and operational transparency.

Yes the real impact here of this Operational Transformation

is not just that devices are becoming smarter, “self aware” but the need to

gain consistency in operations, and reduce errors. There is significant

discontinuity happen in the market, as the logical way to eliminate the errors

is through experienced workforce. As we all know that actually the workforce in

5 years will dramatically be less experienced than the workforce of yesterday

or today.

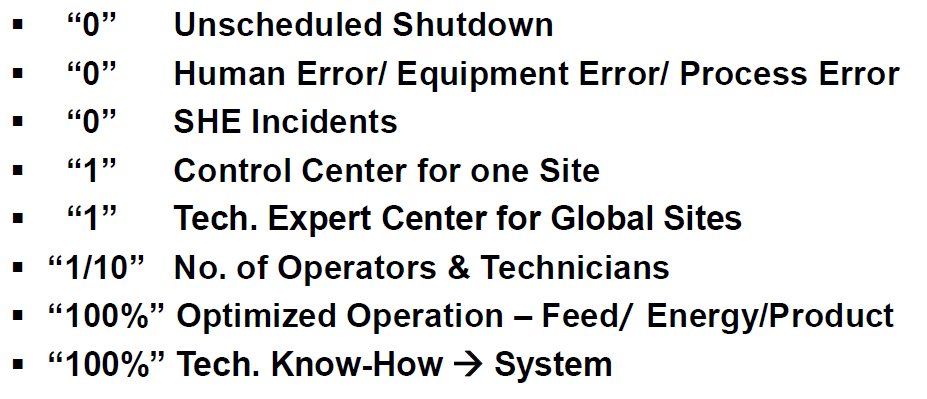

The diagram below shows the experienced workforce today is responsible for most of the

unscheduled shutdowns.

So the outlook in the next 5 years is grim as we move to the

in experienced workforce, unless our systems and operational processes change that

is why “smart xxx” is real.

The major outcomes of the drive towards “smart factories, airports,

fields etc” is to embed the operational experience, and self awareness in the Smart

Devices” and “Smart Processes” .

Too often we do not have clear goals, but it was interesting

to see a leading coming define very clear goals constantly to monitor the

direction, and success of this "journey".

Below is their goals:

Key drive is for zero human, equipment and process shutdowns

and errors; this drives towards a significant embedding of process and automation

on process and analysis to predict situations so that planned / controlled

actions can take place limiting unnecessary shutdowns.

Key is the recognition that number of experts that are going

to be available due to new generational work-space is going to be limited, and

it is key to dramatically reduce the dependency on these experts by 90%. Another

shift is to Global centers of excellence that must have access to timely information

in context and trusted to interact with the local teams.

100% optimization of Feed/ Energy/ and Product usually plant

have 1 maybe two of these tuned , but not 100% optimized, but this is not as

simple as it looks when Feed stocks vary, Products instruction is increasing

and Energy is totally variable, but the company has recognized to minimize impact

of variability is optimization. Also the knowledge of the system must be

embedded, so the system is intuitive and self aware, enabling operational

workers to rotate while maintaining consistency in operations and process.

Intelligent Alarms, and awareness will have to natural, so

state / condition pattern analysis the move to the “to be” state is key. Many

companies have significant programs in play now for transforming their current

alarm structure to enable rapid, intuitive awareness of where that “pin” is in

the haystack of alarms, and events.

As the plant becomes more intelligent and able to operate,

key decisions and follow through actions in a timely manner are fundamental.

This will not be one person; it will be a set of actions, and decisions across

a team. So the operational system will be designed with collaboration in mind,

the natural ability to guide, have built in operational process, natural documentation

of actions, and passing of actions to the next person. Key will be the ability

to “Resolve Operational Tasks” through tracking and an operational work system

within the system, optimizing the human assets as much as the physical assets

and processes.

No comments:

Post a Comment