As I enter another week of brainstorming workshops across

Schneider Software, with thought leaders, we are working through innovations on

technology, architecture and process. Centered around the “cloud” and “Internet

of things” while we have offerings happening in both areas, we need shift from

offerings to these technologies be a natural part of the industrial

architecture and process of buying and applying an industrial solution. I also

spoke with many people over the last 2 weeks across the world not about

technology but about the solution challengers and it was clear that the three

main challengers kept coming up:

- People and operational change of moving to teams which involved remote workers and virtual experts

- Agility to change production, and process quickly and efficiently

- Holistic control across the manufacturing industrial assets. This required the expansion to assets that could be mobile or remote to traditional industrial plant, yet still are apart of Value Chain that they are accountable.

Accountability came up over and

over again; this means different things from a safety of people to food safety so

trace ability etc to efficiency and responsibility to the environment and impact.

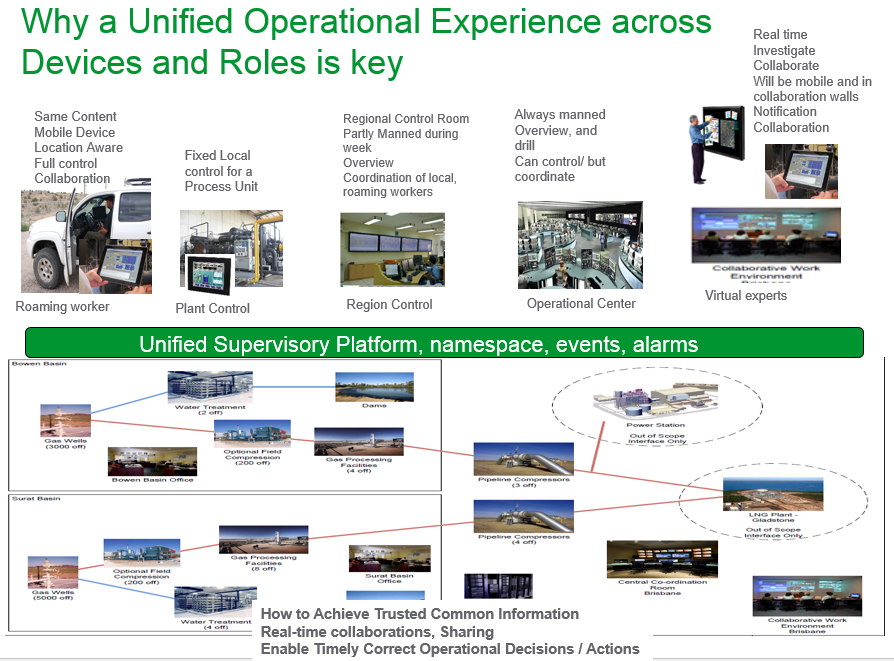

It was clear in all the discussions that a change in thinking of architecture

and approach was needed but instead of its being a “dream” it is really

possible today in a sustainable way using such technologies as Cloud and

Internet of Things. The architecture below is an example of distributed, but

needing a unified operational experience across roles across devices, and

unifying devices.

Also during the week I came across

two articles one from Microsoft and another from ARC on Hanover fair both

supporting the increased momentum in the market for Internet of Things.

Key as MS points out below the opportunity to

investigate and improve your business by naturally looking beyond the

traditional architectures, overcoming the concerns such as security, by implementing

secure architectures and approaches “that does not mean isolation”.

The Operational Transformation is here from a design point of view, again this is one of the technologies and approaches to be employed to achieve the operational workspace and efficiency required in the flat world.

It is indeed a good article.

ReplyDelete