I wrote about this 2 months ago, but seem to have spent the

last two weeks talking and working through this “managing of Variability/

variation” as key. Too many people said that you are forcing standards, but

these only come once you have a platform of abstraction on top of variation you

want manage or accommodate.

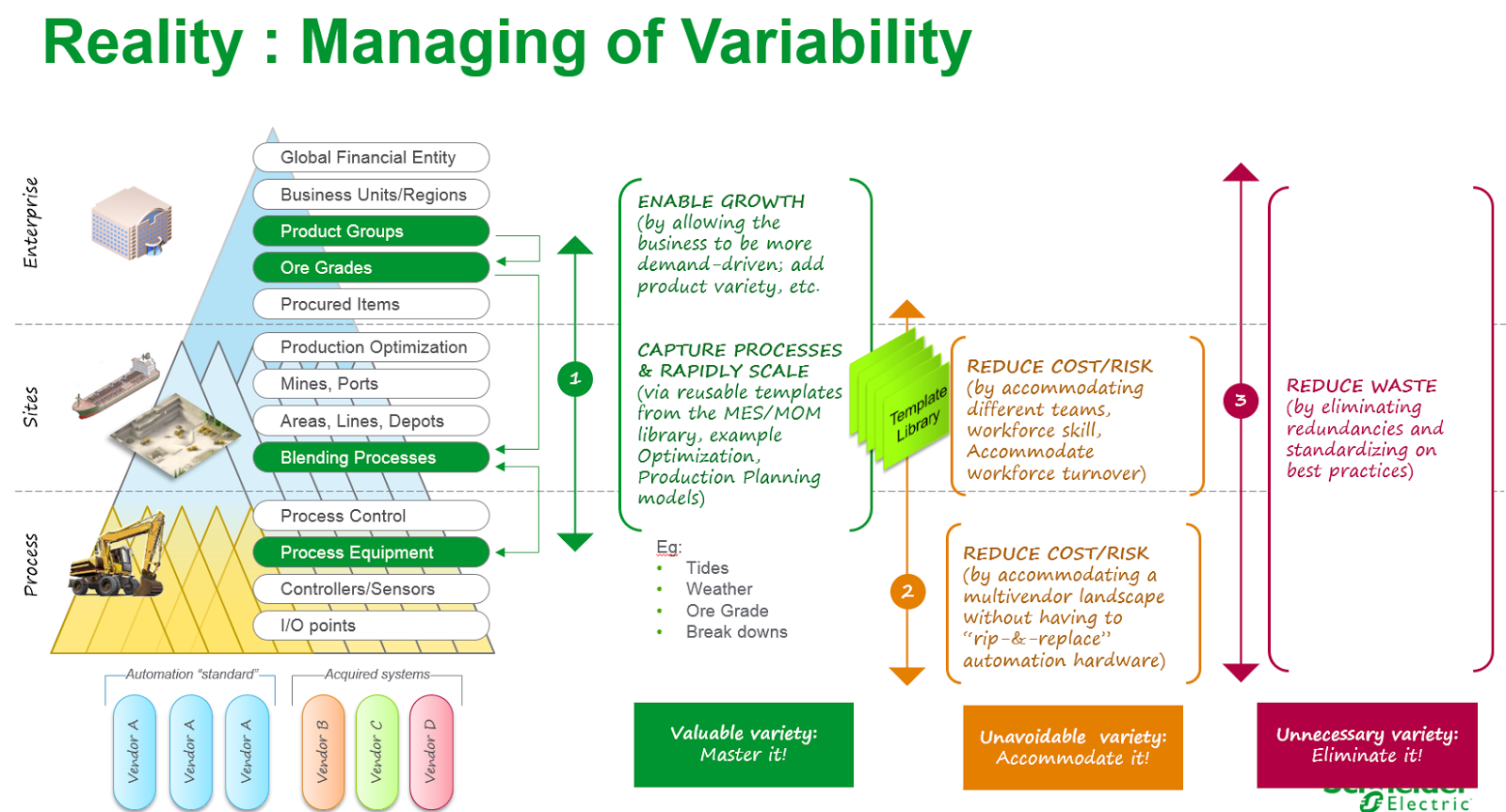

“How do you manage

this Variability, so that production

consistency, agility and increased production output are achieved?” While the

concept of everything being a standard would be great, it is not practical and there are variability’s that we

must “manage” and others we must “accommodate”.

The goal of business is to make a profit.”

- Continuous Improvement Leader

Thus, any standardization effort must distinguish between

the different types of variety in a way that maximizes profit without

constraining the business strategy. Thus, the business challenge can be summed

up (using the mining example illustrated in

the above) as follows:

- Mastering necessary variety: When running a mine or plant, such

things as Ore Body quality (raw material quality) that varies not

according to the ideal plan. Breakdowns of

equipment, weather like hurricanes/ cyclones disrupt ports and operations,

tides effect ships coming into ports. These are “necessary variability” that

all must be “mastered” to optimize production, operations, and you

need to put systems in that allow you change plans and strategies as required.

I had one workshop last week where the team

was looking at long term strategies in the traditional sense. They had not

adjusted their thinking to a long term strategy now has to make of shorter

operational plans that can be adjusted in “near real-time” due to “master”

these “necessary” variability. The operational systems must empower

all people to be planners in their time span, to empower actionable decisions

that are related to achieving the

bigger strategy, and clear impact is understood. As products, deliverables change and vary

more regularly, plans will become shorter and increased volume of plans to

achieve a business strategy.

- Accommodating unavoidable variety: Situations like different automation

vendors or implementations across equipment, processes and sites. It is impractical

to think a company can acquire new or existing equipment and processes and

expect a particular PLC or automation system, the OEM equipment suppliers

just make the change to cost prohibitive. In order for companies to grow

and be agile, they must “accommodate”

natural variety from equipment suppliers, existing sites, but be able to

apply their operational standards/ processes across the different

equipment. Another area that that

limits operational excellence is the different “experience” levels of the workforce,

from shift to shift, from site to site. The operational systems must

abstract operational/ or site experience by embedding operational

procedures/ actions into the system providing a guidance and consistency

of operational decision and action. This

starts to generalize the workforce experience enabling significant

operational workforce flexibility between sites, and hiring, addressing

the challenges of workforce / skill shortage.

- Eliminating

unnecessary variety: Anything other than the above two scenarios

would be eligible for standardization.

It is NOT about “rip and replace with standards it is about “mastering and accommodating” these variations

while enabling operational excellence growth and continuity by applying

operational standards across this variability. Key is “platform strategies”

that abstract the variability and can absorb variability while provide a

platform for services that enable

standards to be built on. Providing the architecture for “sustainable

innovation” through managed standards that can evolve over time. Standards can

be operational models in supervisory for alignment of context and structure, as

well as operational actions to guide users through tasks in a consistent way. Also,

configuration of control strategies should be over multiple vendors, where

common control standards for process can be deployed over multiple controllers

but managed in structured way.

Does this mean one platform? NO, not for the industrial

landscape different layers of the industrial operations landscape have

different roles. Providing different services and different ability to absorb a

variety, but the common services between

these platforms must enable them to “tightly aligned but loosely coupled”.

As we have pointed out the

key to success in this dynamic but changing world is the ability to “Master Necessary Variety” in your

business, while “Accommodating

Unavoidable Variation”. Providing a structure to acquire new “brownfield

plants” accommodate their existing automation and process. But apply the

new companies’ differentiation through applying their operational procedures

across these acquired plants.

This is not a new

concept, but I seem to explain it a lot now

days!!!!

No comments:

Post a Comment