One of the nice things of this time of year the meeting

workload drops, providing the opportunity to do some much needed catch up of

reading. An article that sparked some interesting thoughts and is related to a

lot of the principles of work and activities. It is worth a read on Toyota’s

approach to management of standards around the fundamentals of operational

procedures.

As discussed at length this year there are a couple of

key approaches that will effect industrial operational design:

·

That design needs to move away from interfaces

to actually design around activities/ Work; these can be executed through any

interface hosted on any device.

·

The other trend is to move to manage /

planned work, a knowledge worker moves from a “fire fighting” mode to a 70+ %

planned work in a day, which increases safety, and consistent process execution

through operational process stands combined with significant cost reductions

due reductions in the planned time.

These two trends or approaches will grow in adoption in

2014/ 15 as it is the only practical way to deal with the changing dynamic

nature of the workplace and rotating workforce.

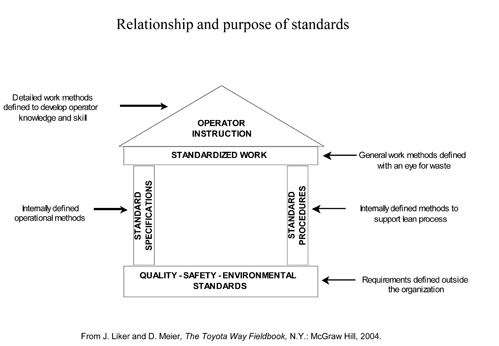

The structure outlined below by Jim Laker used at Toyota

is a good basis for the how to lay out standards in procedures vs the actual

operation instruction. But another key cornerstone of this is knowledge management,

with 10000 baby boomers retiring a week in the US, and this rate is expected to

sustain for the next 17 years, the requirement for skill vs the talent pool

will be offset. So the operational systems must incorporate shared knowledge,

crowd sourced and managed to maintain the value. Many of the operational procedures

and best practices must be captured over the next 5 years, companies must put a

maintainable knowledge management system, and culture in place, and as you can

see in this diagram that standard procedures, operational safety and

environment procedures, and practices form the basis for the transition to

planned work, and activity based systems.

When you think of standards you think of “handcuffs” on

design and therefore innovation, but this is not a logical thought process. How

do you enable operational innovation which is based on operational best

practices, provides the foundational platform on consistent execution to enable

innovation and movement forward. The need to capture operational innovation by

taking the best operators and knowledge workers based on years of practices, capture

their operational practices within a system so that new less experienced users

to adopt the proven practice. Is this a one off NO, this is the continuous

process of improvement which will provide the edge for companies to agile.

As you sit down for the Christmas pudding and we look

forward to 2014, there is much opportunity and change ahead of us, and these

articles provide solid food for thought.

Have a great festive season, and see you in the new year.

No comments:

Post a Comment