Too often over the last 6 months the desire for managed calculations has come up when reviewing a project or site. Drilling in on the requirements it becomes clear, that the enterprise’s/sites are having trouble aligning, managing calculations/ measures and KPIs. Microsoft Excel has become the source of many of the calculations, providing the freedom for engineers to create Adhoc calculations. The Excel paradigm is an isolated one, ending up with 100s / 1000s of calculations. Many of the companies I talk to across different industries have initiatives underway to eliminate Excel as data source, they do not mind it as an analysis tool. The major chunk of work is to understand the current Excel sheets determine the measures and calculation within these, determine the common calculations and data sources, and then determine a way to create and manage calculations/ measures and KPIs with clear governance. Not and Easy Task!!!

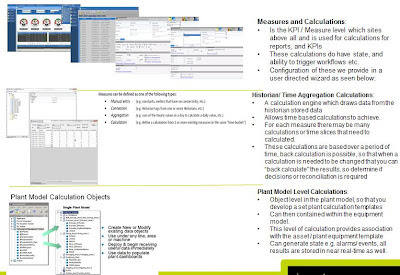

Historians have had calculation engines associated with them for years, but this is the middle class, and looks at time series and summarizes, aggregates data based on time slices. This is key, but we see the increasing need for lower level calculations associated with equipment types, for delays, throughput, mass balancing etc. It is key that these equipment/ area calculations are apart of the templates of equipment, providing consistency across the instances. The hierarchical management of these calculations / measures so evolutions can happen and be easily rolled out across a site or sites. Also, these plant associated equipment calculations require having state, with the ability to trigger alarms/ events and workflows in a pro- active manner.

The top layers are what people call KPIs these will come across equipment, sites and creating realtime and historical measures and then KPIs'/ calculations. These KPIs need to have state ability to be seen in dials, dashboards and be stored. They trigger operational boundary conditions for operators, plant and process people. They could be off site and at the enterprise, also triggering procedures based upon exception conditions.

When starting to look at this landscape, calculations and measures will be dependent on other calculations and the quality of these calculations. Also, the requirement to understand the impact of of calculation changes, providing a governance and control on these calculations. Driving the requirement for the ability to visualization a spider dependency view/ graphic across calculations. Companies will have to revisit their architecture, and how they will manage these calculations in order to achieve the full value longer term, as they will continue evolve. It is essential that a more holistic view is taken vs just one set of or class of calculations (e.g.| Historian as they form only one part of the jigsaw).

Certainly Invensys is evolving the ECS’s (Enterprise Control) approach to calculations at all levels based on the common drivers we seeing.

No comments:

Post a Comment