Business Control Loop Concept Critical for Continued Process Improvement.

Nearly all customers/ end users I am talking with across multiple industries have a “lean/ performance program” looking at business processes and supply chain. Many have adopted techniques such as Lean/ Six Sigma, and many have a dedicated team investigating and driving performance thinking across the different aspects of the business.

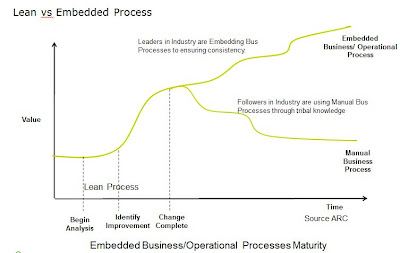

The diagram below came from ARC on a survey they did, but it is the best depiction I have seen how the leading customers gain an advantage by embedding processes vs just training and manual implementation. The leading companies are looking take this embedded process, to the operational space, and again this becomes critical in the “rotating” worker world.

In the last 5 years we have seen significant increase in so called MES applications been applied, this could be in Batch, MES, Quality, KPIs, but really what is happening is that a “Business Control Loop” is being implemented. Based on a business process the operational execution procedure best practice is implemented in a workflow/ process. This is then rolled out across multiple sites/ or like processes. This does now restrict the freedom on how to execute this process, but in turn you gain the consistency in execution, and ability to understand execution and where to improve by reducing variation. This naturally solves to issues:

· The ability to gain consistent execution over different sites/ cultures

· The consistency of execution across shifts/ operational teams, but most of all as we go into the transition of staff through rotating roles (discussed in early blogs “The Perfect storm in Industrial Operations= People Excellence Feb 2012”). As one customer stated we have design to assume limited experience, through embedded procedures you immediately solve this by an worker being able to understand a situation, and the associated activity and be provided with recommended procedures to work them through this.

These procedures can and should have built in help and self-training even built in certification if needed so there is a record that the worker has gone through the online training, and now the procedure will guide him through.

The leading companies are now building this capture of best practices into “embedded processes” as they learn them, even dedicating the more senior members of the team to document their experience in procedures that can be then embedded. In many ways traditional MES products with their routes and operations enforce this process in the product execution, but we now finding this happening in process and utilities.

This is why we saw the need to build in ArchestrA Workflow as a natural extension to the ArchestrA application model, not an add-on, not a BPM (Business Process tool) but as an operational process extension to the real-time supervisory and control system. Just a simple thing as an alarm can now have workflow monitoring it, based on other conditions and alarm could be generated but due to the other conditions in the plant a workflow may automatically escalate the situation and notify potentially others. What we have done is taken knowledge and built a situational aware capability, which aligned with the best practices the company wants to implement. We are seeing the same approach on NPI (new product introduction) where one of the biggest challengers is to enter the correct set-up data across multiple operational systems. The room for error is huge and lost time in revalidating and fault finding not counting lost production time and waste. Implementing procedures and alignment of data models is a big step in the correct direction. The whole focus on "Operational Safety" that naturally embeds best practices into day to day operations to avoid safety sistuations, is another example.

So when you looking at designing operational/ supervisory systems, you need to think of it not as a project but a journey. Yes the initial project gets you to a certain value and point, but the culture should be a continuous one of looking to capture best practices and embed them (so this must be a natural act not an exception), so the new value and improvements are gained for all as you learn. This requires a change in both the products vendors supply and the way in which endusers and engineering houses go about implimenting operational execution programs, but there is no choice if they are stay compeditive.

No comments:

Post a Comment